Industry Leadership & Reputation

Certified Quality & Compliance

Comprehensive Product Range

Innovative ODM & OEM Services

Commitment To Excellence & Partnership

Factory Area

Production Line

Employee

Capacity

The metal is smelted into a liquid that meets certain requirements, then poured into a mold to cool and solidify.

This is achieved by applying layers of fiberglass and resin to the acrylic shell, resulting in a strong and durable structure that can withstand water pressure and long-term use.

Put the blank into the extrusion barrel and apply pressure to make the material extrude from the container.

Use compressed air or spray cooling, and lubricant can be added simultaneously when spraying.

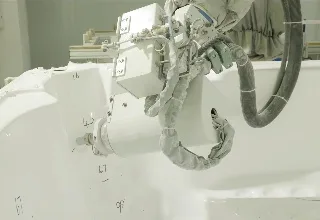

The material is heated to a molten state and then pushed by gas or air to form a deposit on the receiving part.

Attach durable, weather-resistant outer cabinets to the reinforced shell and frame for structural support and aesthetics.

We wrap the spa tub with protective film and foam, then secure it with corner guards and place it on a reinforced pallet for safe transportation.

Ready to learn more? Fill out the form and a member of our dedicated team will reach out to you promptly!